Parallelometry is a science that consists in examining and determining the parallelism of the axes of supporting teeth, is used in orthopedic dentistry during the development and manufacture of high quality dentures.

Parallelometry is a science that consists in examining and determining the parallelism of the axes of supporting teeth, is used in orthopedic dentistry during the development and manufacture of high quality dentures.

In the case when several clamps carrying out the supporting-retaining function are included in the prosthetic construction, it is necessary to determine the correct position of their shoulders in the support and retention dental posts.

This work is done so that when fixing the dental prosthesis, and also when positioned in the mouth, the support clamps do not loosen the teeth of the support points and distribute the pressure during chewing of food strictly on all the teeth of the prosthesis.

Applied equipment

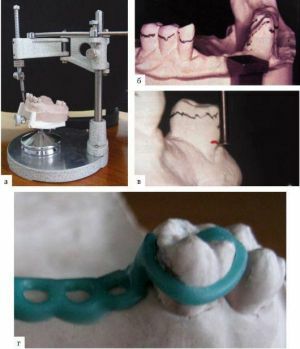

Parallelometer is a device that determines the parallelism of teeth or any parts of the modeled jaw.

The principle of operation of the device is that in any direction the rod is displaced, it must always be parallel to the initial position.

The dental parallelometer does not have a complicated design and consists of the following basic elements:

- Rod .Located perpendicular to the platform and fixed vertically, without tilting. Can move horizontally, as well as up and down.

- Table .It is located on the platform itself. It is on him that the simulated jaw is installed to check the parallelism.

- Table leg .With it, the table is attached to the platform, and also adjusts its position in the slope and height.

Modern, modernized instruments have in their composition not one rod. They are equipped with an analyzing rod with a disk, for measuring and detecting friction, graphite, for delineating the waist line and a blade that serves to cut off wax surpluses.

How are jaw models made?

The study of the model of the jaw begins with its manufacture. Mold the model from a high-quality durable gypsum, after which it is dried and carefully cut off from all sides( combed).

The study of the model of the jaw begins with its manufacture. Mold the model from a high-quality durable gypsum, after which it is dried and carefully cut off from all sides( combed).

The finished base of the jaw must not be less than 1.5 cm. The walls located on the sides of the model are necessarily parallel to each other, as well as perpendicular to the base of the jaw.

Manufacturing of clasp prostheses, one of the stages of which is parallelometry:

How is the model tested?

Initially, the finished model of the jaw is placed on the table of the device. After this, the holding points of the teeth are examined, and then the model is brought to the analyzing rod of the parallelometer. After the work done, randomly scroll the table in different directions. This is necessary in order to find the position of the jaw where the angle found by the device will be parallel to the angle of the retentional surface of each clamping tooth.

In this case, the most favorable conditions appear in order to properly locate the shoulder of the clasp, which performs the retention function. It is in this position and fix the table. The next step is to delineate the belt with a graphite  rod.

rod.

Belt, which is located on the teeth, performing a chewing function, often passes through the contact points of the contact side. On the tongue surface, the belt passes almost in the middle of the dental crown, but on the vestibular surface it descends towards the neck of the tooth.

After the general belt line is found, find out where the support-retaining clamps will be installed. Of course, it is not immediately possible to determine their future location, which is why, using calibres, they reveal how pronounced the retention surface is. Next, determine what kind of construction will have a fixing clamp.

The dental parallelometer has three calibers( d = 0.25, 0.5, 0.75 mm).With their help, they reveal where the ends of the clamper's shoulder perform the restraining function, then mark them with different colors in the region of the supporting teeth.

To determine from which point the beginning of the pattern of the fixation bracket on the support tooth will occur, a gauge is attached instead of the rod and attached to the retention area.

With the help of moving the caliber up and down determine its position where to the tooth will simultaneously touch both the caliber and its rod. It is from this point and will begin the drawing of the clammer, which is applied in such a way that only one-fourth of his shoulder is lower than the tooth zone.

When the drawing is ready with a pencil draw arcs and other parts of the future prosthesis. After this, the obtained retentions on the jaw model are filled with wax, and the excess wax drops are cut with a blade. After the work done, the parallelism of the teeth is created.

A denture is made using a finished model.