Few of today's youth have heard of such dental products as stamped crowns, but they can still be found in middle-aged and elderly people.

Few of today's youth have heard of such dental products as stamped crowns, but they can still be found in middle-aged and elderly people.

These elements are made of a metal base, they are put on the tooth and replace its functions. Since stamped products have an inexpensive basis and are fairly simple to manufacture, their cost is quite low.

Stamped crowns are one of the available ways to repair the damaged structure of the teeth.

The design is made in the form of a metal cap, which is simply worn on the surface of the tooth. This method of prosthetics has been used for quite a long time, but recently such crowns have ceased to be in demand among patients.

This is due to the non-aesthetic appearance of these products compared to cast and other types of crowns. In place of stamping come more expensive products, the structure of which is as close as possible to the appearance of real teeth.

Contents

- What materials are used

- Indications for installation

- Advantages and drawbacks of

- Features and manufacturing steps of

- Procedure for preparation of

- Important nuances of manufacturing and installation

- Care details

- Life expectancy

- Patient opinion

- What will it cost?

What materials are used

Die-cast crowns are made of a metallic material that can be sprayed or without it.

spraying The

gold-plated crown is usually made of noble materials - gold or silver. The greatest demand is for crowns with gold plating.

Previously, these products were made without spraying and were in high demand.

Currently, stamping is usually used by people with small incomes, because other designs that are made of ceramics or high-quality plastic, are quite expensive.

Indications for installation

The stamped metal crown is used in the following cases:

- for restoration of the dental unit in the presence of a defect in the crown part of the tooth;

- in order to protect a healthy tooth, on which a clasp prosthesis is subsequently installed;

- is used as a protective element for supporting teeth when installing bridges;

- in pediatric dentistry for the protection of infant teeth, which are at the stage of destruction.

Advantages and disadvantages of

The positive features of the stamped products include the following:

- is a low price, so at a cost, stamped crowns can fully compete with plastic products, and, of course, they are much cheaper than porcelain products that are made of cermets;

- simple construction;

- fast manufacturing;

- can be used in cases where it is difficult to apply other methods of prosthetics.

The negative qualities are as follows:

- after a certain time there is complete dissolution of the cement fixing mixture;

- if the crown has a loose fit, then residues of food may enter the spaces between it and the tooth, which subsequently cause a carious lesion of the tooth enamel;

- , the alloy of the stamped crown is not particularly strong and during long-term use, the abrasion of its base occurs;

- lost functions are not completely restored.

Features and steps in the manufacture of

During the clinical phase, the following procedures are performed:

- is primarily preparing for the installation of the crown - the tooth is grinded;

- then selects the color of the product according to the preferences of the patient;

- from the dental unit to which the crown is to be installed, the impression is taken;

- after this cast is transferred to the technician who makes the necessary crown;

- the doctor performs the fitting of the crown on the tooth and makes further adjustments;

- at the end is fastening the crown.

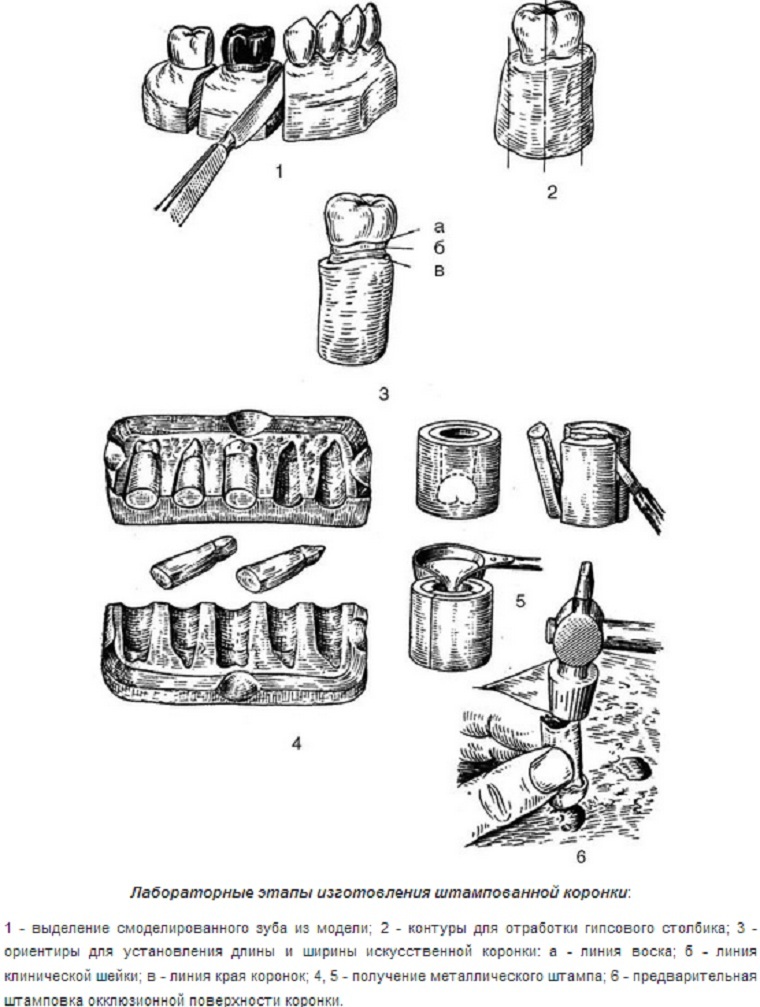

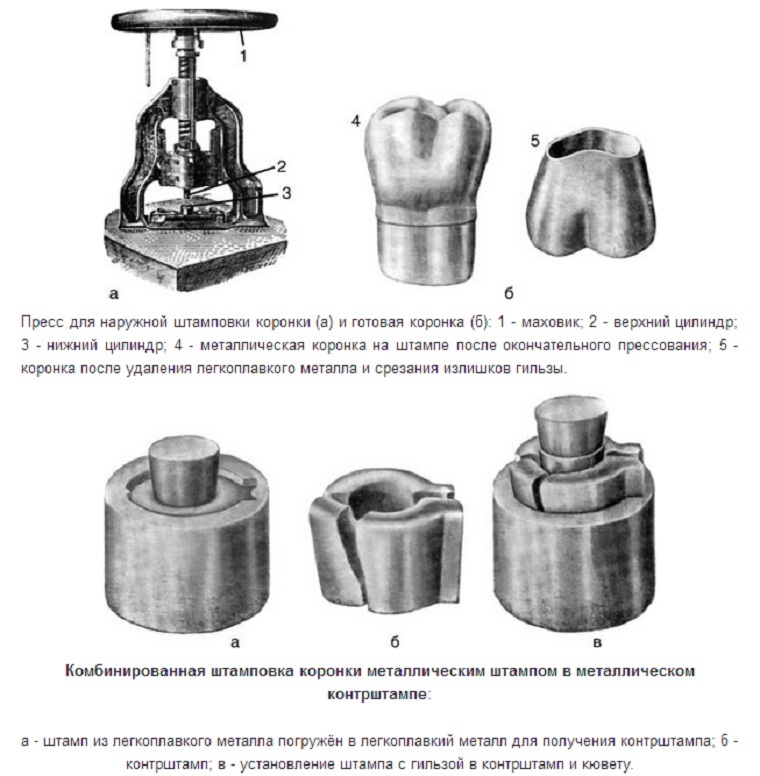

Laboratory stages of manufacturing:

- on the basis of casts a model of gypsum is made;

- further places the jaws in the region of the central occlusion;

- at the next stage, the melted wax material is applied in the form of layers on the gum area and a wax model is made;

- is further made a stamp of gypsum material, and then made of light metal alloys;

- further the selection of the sleeve is made, which is necessarily given the necessary form;

- at the end of the whole production process, stamping of the crown is performed and it is transferred to the dentist for further installation.

All stages of manufacturing the stamped crown visually with video and photos:

Procedure for preparation

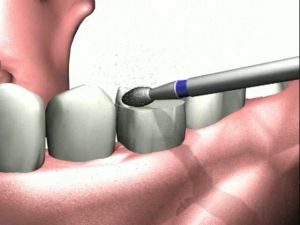

Preparation of a tooth for a stamped crown has distinctive features in comparison with other types of products. During this process, a thin layer of tissue is removed.

The entire preparation process is performed as follows:

- The first step is to prepare the preparation with diamond wheels, with which the removes the top layer of the tooth to a thickness of up to half a millimeter .The thickness of the layer can fluctuate, it all depends on the type of material that will be used in the manufacture of the crown. The size of the layer being removed is affected by the spraying of the crown. For example, if the crown has gold plating, then the removal will be quite large.

- At the subsequent stage of the , a space test is performed that divides the tooth and its antagonist .The size of the space must be appropriate. For verification, a special strip of wax material is used. The patient bites the strip. After that, the print is evaluated, which remains on the strip.

- After this, is prepared for the preparation of the proximal surfaces. For this, special disks of diamond material are used.

- At the end of the whole process is performed to prepare the buccal and palatal surface of the in order to give the stump a cylindrical shape. It is important that the diameter of the stump does not differ from the diameter of the root of the neck.

Important nuances of manufacturing and installation

Conditions to be considered during the manufacture and installation of stamped products:

- The installed product must tightly grasp the area of the neck of the tooth. If the crown is wide, then there may be a process of irritation and displacement of the gum tissue, as well as its further atrophy. But the clearance in the manufacture of crowns still remains, it is filled with cement, which eventually dissolves completely.

- The immersion in the groove area should not exceed 0.3 mm. If the dive is greater, an acute form of marginal periodontitis may form.

- The installed crown must fully restore not only the chewing functions, but also the full functionality of the tooth.

- The crown should observe the full anatomical structure of the tooth. It should have all the necessary knolls, equators.

- During the contact between the crown tooth and its antagonist, the interhelveolar height should not be exceeded, otherwise the risk of injury may increase.

Care features

After installing the stamped type crown, the same oral hygiene rules must be followed, as usual. The main condition - care of the oral cavity should be thorough and regular.

Recommendations for care:

- is necessary every day in the morning and evening to clean the oral cavity with toothpaste and brush;

- the oral cavity is recommended to be cleaned or rinsed after each meal and smoking;

- in order to remove food residues from hard-to-reach places, it is recommended to use a special dental floss.

Do not forget that three months after the installation of the crown is to come to the examination to the dentist.

Do not forget that three months after the installation of the crown is to come to the examination to the dentist.

The doctor will be able to inspect and assess the condition of the crown.

It is imperative to visit a doctor every three months, this will help to avoid serious problems, for example, carious tooth lesions under the crown.

Service life

The service life of stamped crowns is not long, only 2-3 years. But many dentists recommend to change them in a year, because during this period, gaps can form between the crown and the tooth, as a result, food particles can enter into the interior, which can subsequently have a harmful effect on the tooth structure.

Patient's opinion

Patients who received stamped crowns.

As a result of deep caries, which led to complications, several distant teeth were removed at once. As a result, there were severe discomforts with eating and chewing.

The dentist recommended installing stamped crowns with gold plating. After all the tissue was restored, I turned to the doctor to install these products.

The procedure is certainly long, but in principle tolerable. Two weeks later, I was fitted with a crown, to which I quickly got used. While I wear it for about a year, on the whole everything suits me.

Ivan, 45 years old

I am engaged in professional winter sports, namely skiing. On the next race I fell heavily and hit the jaw area. After a while he found a strong pain in the tooth and immediately decided to go to the dentist.

On examination, it was discovered that I had a crack in my tooth. The doctor treated everything, installed the seal, but recommended to additionally install the crown.

I chose a stamped crown with a plastic lining, it almost does not differ from a real tooth. Of course, the installation was lasting, but now I know that the damaged tooth is protected from negative effects.

Sergey, 36 years old

After I gave birth to me, just one after another, my teeth fell. As a result, I lost almost 5 chewing teeth. First I wanted to install implants, but they are quite expensive.

The dentist advised to use stamped crowns. I chose crowns with plastic lining and spraying. Still, it is much cheaper than implant implants.

Perhaps in the future it will be possible to save money for implants, but so far I'm happy with it.

Irina, 33 years old

What will it cost?

The price of stamped crowns depends on the composition and outer coating:

- metal costs about 1500 rubles;

- the stamped crown with a dusting will manage in 1700 rubles;

- with a lining made of plastic material costs 1900 rubles;

- product with facing and spraying costs almost 2100 rubles;

- products with a clasp design cost 1800 rubles, with spraying - 2000 rubles.