Application of CAD / CAM systems in dentistry allows to design and manufacture prosthetic orthopedic structures using a computer.

Application of CAD / CAM systems in dentistry allows to design and manufacture prosthetic orthopedic structures using a computer.

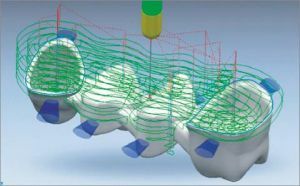

CAD is short for Computer-Aided Design, - computer-based design, is used instead of a drawing board and allows you to create a 3D model of dentures.

The advantages of this design can be attributed to the following:

- model, designed on a computer can be viewed at different angles and examine its projection in a certain light;

- can be replaced not only individual parts of the drawing, but the entire model is designed again;

- a ready project can be turned into an instruction that will be passed on to machines for the consciousness of this part.

There are ultramodern systems that create 3D models, taking into account the structural properties of materials.

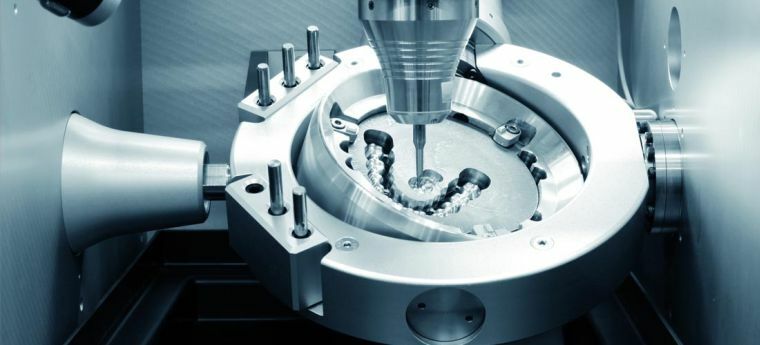

CAM or Computer-Aided Manufacture designates the manufacture of an orthopedic design by a computer in accordance with a previously designed 3D model.

Features and types of CAD / Kam systems

Manufacturing of a dental bridge on the

CAD CAM system allows to produce:

- crowns and bridges of various lengths;

- telescopic crowns;

- abutments for dental implants;

- veneers and inlays;

- provisional crowns.

There are 2 types of CAD CAM systems:

- closed systems that work with a specific consumable, usually produced by one company;

- open systems, working with various consumables of different manufacturing companies.

Prosthetic steps using CAD CAM systems

Prosthetics using CAD CAM systems are as follows:

- A dentist prepares one or more teeth. Then he scans the 3D camera with his teeth and bite, resulting in an optical model. You can also scan regular snapshots.

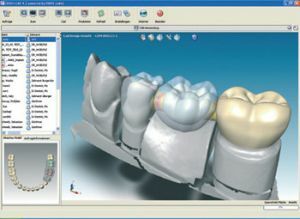

- The resulting image is then processed with a special program that draws a 3D model of the teeth to be restored. She herself chooses the shape of the future restoration taking into account other teeth, but the doctor can correct the proposed design with the movement of a computer mouse. The amount of time to create a 3D model depends on the skill of the specialist and on the complexity of the clinical case. This can take from a few minutes to half an hour and even more.

- When the simulation is completed, the file with the structure of the part to be produced is transferred to the control unit of the milling machine. And here, from a piece of solid material, a 3D model of the part is cut, which was previously modeled by a computer. By the time it takes about 10 minutes. To make the design look more natural, it can be covered with translucent and reflective ceramics.

- When zirconium oxide is used as a material, the further fabricated structure is placed in a sintering furnace, resulting in a final shade, size and strength.

- After firing and solidification of the material, the part is ground and polished. Then you can install the product on the prepared tooth.

Advantages and disadvantages of computer prosthetics

The advantages of using CAD CAM include the following:

- Reducing the timing of the manufacture of orthopedic structures. Do not make traditional casts, which makes it possible to restore the tooth in just one visit to the dentist. Local anesthesia is used only once during the preparation of teeth for the installation of prostheses. If the client is put an all-ceramic bridge, then you need to visit the dentist twice.

- The client can see the end result on the computer, he can independently choose the color and shape of the future restoration.

- If earlier only one seal could be delivered for one dental visit on the basis of polymer resin or mercury compounds, then using computer technology it became possible to use ceramic and composite materials. CAD CAM systems can work with zirconium oxide, titanium, plastics, wax, cobalt-chrome alloy. Ceramic materials have many advantages. They can be mixed in different proportions and match the color of the filling close to the color of the teeth. They are distinguished by good biocompatibility, hypoallergenic and wear resistance.

- The frame on zirconium dioxide is only 0.4 mm, so the grinding of teeth is minimal. And its light shade allows you to avoid the appearance of dark edges, which are observed in many people with cermets, when with age their gums settle. Also, the ceramic seal and the tooth surface can be processed in such a way that they become a single whole.

- Zirconium crowns made with the help of CadCam system, meet all specifications. As the various

studies and practices show, milling dental restorations made with the involvement of computers are more durable than those made without them. These products have a longer service life.

studies and practices show, milling dental restorations made with the involvement of computers are more durable than those made without them. These products have a longer service life. - With the use of computer technology it is easier to refine and customize the orthopedic design.

- With the help of computer technology it is possible to minimize the human factor and, consequently, to reduce the probability of error in the manufacture of orthopedic construction.

- High accuracy of work, when using computer technology deviation from the size is only 15-20 microns, then so when casting they can vary from 50 to 70 microns.

- Unlike orthopedic constructions made by hand, products made using CAD CAM systems do not cause discomfort, do not injure the gums, do not deform with time.

The following can be classified as a disadvantage:

- not every prosthesis can be performed using CAD CAM systems, whether its application in any particular case should be decided by the dentist;

- some restorations may look opaque and unnatural;

- high cost.

CAD CAM system allows you to make crowns and bridges in the shortest possible time. Therefore, those who dream of having beautiful and healthy teeth, but do not want to visit the dentist again and again, should contact the clinic where they use such technologies.