Everything new is well forgotten old. The term "fusing" is not an exception at all. In fact, this is the technique of sintering, melting glass, laid in a certain order with the help of special furnaces. Simply put, the technique of creating stained glass. Previously, such decor objects were created only in industrial enterprises, but with the development of technology, fans of this type of creativity were able to realize their ideas and at home. The fusion kits were on sale.

- Features of fusing

- Preparation of materials

- Technique for

Features of fusing

Let's try to understand, is it really possible to create a stained glass window in fusing technique in usual house conditions? To begin with, the process of working in this technique is very fascinating and interesting. But it is suitable only for the creation of small objects, for example: coulombs, ornaments, dishes, watches, figurines, souvenirs.

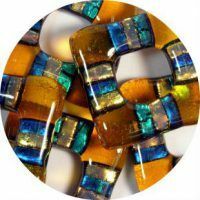

It can be purchased at handicraft shops or ordered on the Internet. It is quite compact, so there will be no problems with its transportation. Together with the stove, it is better to purchase a set for working in the glass fusing technique. It often includes a set of glasses of different types and colors, tools for cutting and cutting glass, heat-resistant paper, gloves and accessories for jewelry. And the last necessary component is a microwave oven. Using its power, it is possible to create a sufficient temperature for melting the glass in the furnace fusing, which is placed directly in the microwave.

With the help of your imagination and patience it will be possible to create incredibly beautiful and original objects. For example, an exclusive watch or stained-glass windows. If you want to improve your creative level, you can always attend master classes on the creation of color glasses in the technique of fusing. Who knows, perhaps in the near future this hobby will grow into a small business project that will bring not only pleasure but also real income.

to contents ^Preparation of

materials So, for works in fusing technology you will need the following materials and equipment:

- microwave oven;

- fusing oven, which withstands heating up to 1100 degrees;

- prints;

- glass cutter;

- heat-resistant fusing paper;

- glass for engineering fusing.

Prepare a sketch of the desired product in advance.

Prepare the glass for work, cutting out pieces of glass from the glass sheets for sintering. It is extremely important that the glass to be treated has the same level of COE.Use glass with different SOEs, because the finished product will be brittle at the junctions.

to contents ^Technique for

Glass parts are cut with a glass cutter, while using oil cutters should be discarded - this can lead to cracking of the glass when heated. Be sure to wear safety goggles when processing glass with a glass cutter.

Having determined the size of the desired product, it is necessary to cut out a piece of heat-resistant paper so that it is slightly larger than the size of the product. Next, you should transfer this heat-resistant base to the bottom of the stove. On it, from the prepared pieces of glass, lay out the desired shape or pattern.

After preparing the glass, we turn to the preparation of the stove. First it is necessary to remove the glass plate from the microwave oven or turn it upside down - it should not spin, because the sintering pattern may shift.

Next, carefully, in order not to disturb anything, transfer the stove with the product to the microwave oven.

For each microwave oven, the sintering time of the glass will be different, and also will vary depending on the number of layers of the product. You can select the optimal one only by experiment.

So, putting the glass in the stove, you'll see that in its upper hole appears a glow of orange - this means that the glass has already begun to melt. Its intensity depends on the completeness of the fusing technique. At full fusing, the glass is melted into one whole mass, and if it is incomplete, the glasses are simply sintered. You can adjust the intensity of the process by adjusting the power of the microwave oven, as well as the time the glass is exposed to microwaves.

Set the operating time of the microwave first for two and a half minutes, after this time, open the lid of the fusing oven, without removing it from the microwave, to check if the glass is enough for your product. If not, then continue the work, adding a minute or more. Most manufacturers do not recommend exposing the glass to melting for more than six minutes, as this can damage the stove. In an average microwave oven with a power of 1000 watts, it's enough 2.5 minutes for sintering a two-layer product, for a three-layer sintering, four minutes will suffice.

After sintering your product, remove the oven from the microwave oven and place it on a heat-resistant surface( ceramic tile, metal grill).Do not open the fuser cover, as the glass should solidify under the closed lid for thirty minutes. Otherwise, due to the temperature drop, the final product will become brittle.

After your glass has caked and stood for at least half an hour, you can get it out of the oven. Depending on the type of glass used, the process time and the power used, you will get different results.

Where to apply such a glass - your fantasy will tell. Beginner masters usually make beautiful pendants using fusing technique. If you take small pieces of glass for melting, then from their fused details you can make a more extensive decoration, for example, beads.